News

Clean tech the answer for companies working to cut energy costs

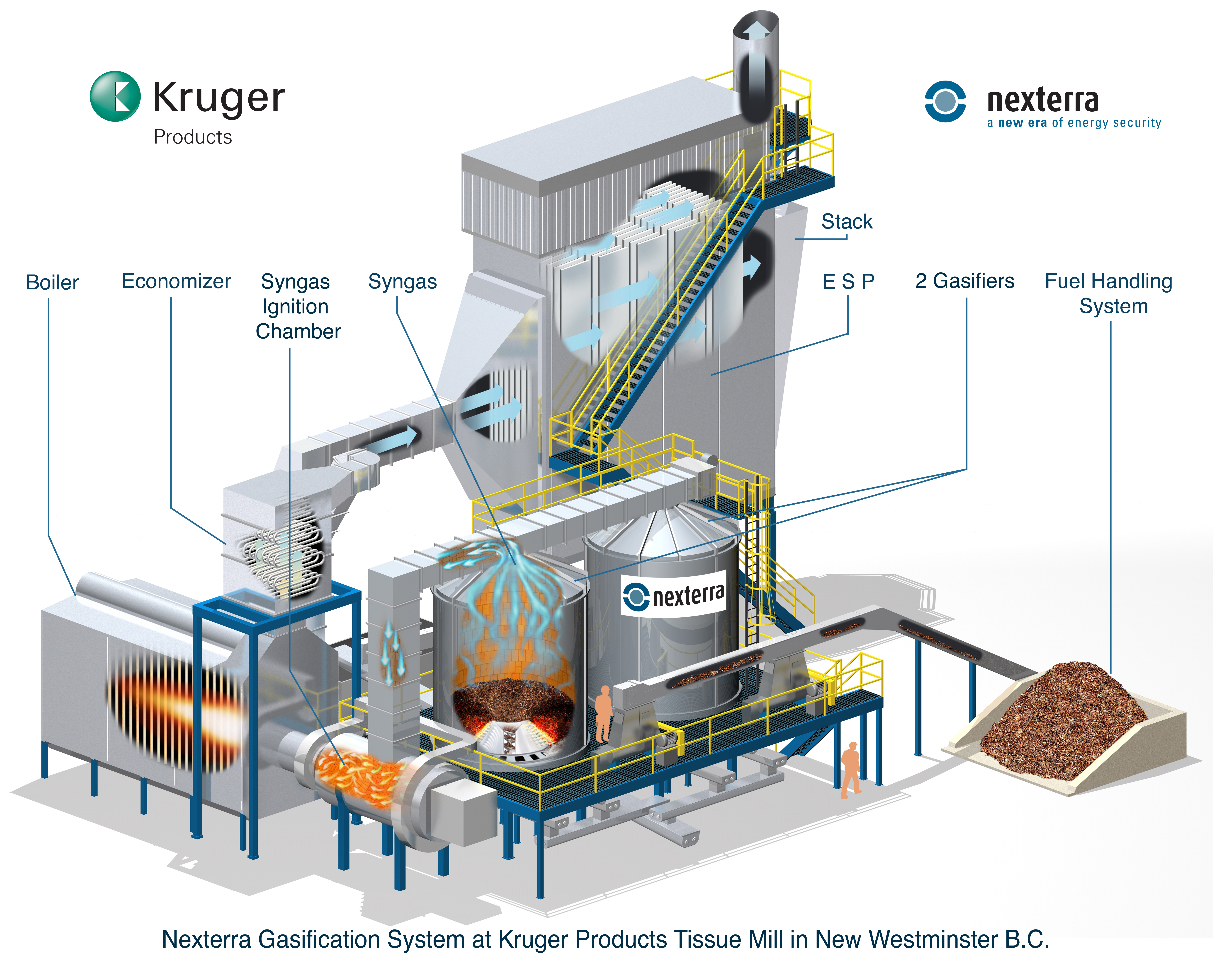

Nexterra Energy Corp. announced on November 19th that its technology has been selected by Kruger Products Ltd. to supply a biomass gasification system for its tissue mill in New Westminster, B.C. The new system will be the first of its kind in the pulp and paper industry, and is another indication of how Canadian-developed clean technology has an important role to play in improving energy efficiency and greenhouse gas emissions in a changing marketplace.

Nexterra Energy Corp. announced on November 19th that its technology has been selected by Kruger Products Ltd. to supply a biomass gasification system for its tissue mill in New Westminster, B.C. The new system will be the first of its kind in the pulp and paper industry, and is another indication of how Canadian-developed clean technology has an important role to play in improving energy efficiency and greenhouse gas emissions in a changing marketplace.

November 21, 2008 By Newswire

Kruger Products Ltd. is Canada’s leading paper tissue manufacturer. The company operates facilities in Quebec, Ontario, Alberta, British Columbia, Newfoundland and Labrador, in the United States and the United Kingdom, and has 9,000 employees.

Nexterra’s turnkey gasification system will convert locally sourced wood residue into clean burning “syngas” that will be fired directly into a boiler in place of natural gas. The Kruger installation will produce 40,000 lbs/hour of process steam and displace approximately 445,000 gigajoules (GJs) of natural gas annually. This is equivalent to the amount of natural gas used to heat 3,500 homes in Canada for a year.

Displacing this amount of natural gas with syngas made from wood fuel will lower the mill’s energy costs by millions of dollars a year, making the mill less reliant on fossil fuels. It will also reduce greenhouse gas emissions from the plant by more than 22,000 tonnes per year, the equivalent of removing nearly 5,500 cars off Canadian roads.

“Kruger Products has taken a leadership role in incorporating green technology in our business practices for 20 years,” says Mario Gosselin, COO, Kruger Products Ltd. “Today, we’re at the forefront. Our goal is to be North America’s foremost provider of quality tissue products that embrace a commitment to sustainability for future generations. Our new biomass gasification system brings us closer to achieving our goal.”

“Our New Westminster mill is situated in an urban area, so we needed the cleanest technology available, and in a challenging economic climate, we also needed the most cost-competitive,” said Frank van Biesen, VP Technology, Kruger Products Ltd. “Nexterra’s biomass gasification system addresses both challenges, significantly reducing both greenhouse gas emissions and energy costs.”

Kruger, Nexterra and FPInnovations have formed a consortium to build the new system, the first commercial demonstration of Nexterra’s direct-fired gasification solution. The project has received support from Natural Resources Canada (NRCan), the British Columbia Innovative Clean Energy (ICE) Fund and Ethanol BC.

“B.C.’s Innovative Clean Energy (ICE) Fund invested in this project because it benefits industry, the environment and the people of B.C.,” said Ida Chong, Minister of Technology, Trade and Economic Development. “It speaks to the potential of B.C.’s clean technology sector to help our industries lower costs and remain competitive, while also significantly lowering their carbon footprint.”

Earlier this year, Nexterra announced the successful completion of a two-year testing program to confirm that direct firing of syngas can displace up to 100 per cent of the fossil fuels in industrial boilers and lime kilns.

“Kruger Products’ new gasification system at its New Westminster mill clearly demonstrates its commitment to the environment and the sustainability of the community in which they operate,” said Nexterra’s president and CEO Jonathan Rhone. “Kruger, FPInnovations, Ethanol BC, and the federal and provincial governments have been tremendous partners in this project, and we look forward to completing the plant later next year.”

Jim Dangerfield of FPInnovations said advancements to Nexterra’s gasification technology makes the switch from fossil fuels to syngas an attractive option for many of North America’s pulp and paper mills and other industrial sites.

“Nexterra’s direct fired gasification system is a platform technology that can be used in many industrial applications,” Dangerfield said. ”Replicating Nexterra’s technology at industrial sites in B.C. could result in an estimated 200,000 tonnes of greenhouse gas emission reductions in British Columbia annually by 2020.”

For more information, visit www.nexterra.ca

Print this page