Industrial

News

Energy master plans: Streamline operational efficiency and reduce costs for companies with high energy usage

Not too long ago, making decisions about a company’s energy management and sustainability was a fairly uncomplicated process for most facility managers: switching to fluorescent lighting, replacing the HVAC to a more efficient system or upgrading to a more integrated process controls architecture to streamline production. These and scores of other initiatives may have been undertaken to make a company more energy-efficient, productive and sustainable. But today it is different. For industrial and manufacturing companies with large campuses or multiple facilities, possibly operating with different production systems and scattered across various geographic locations, managing such a task can become a significant challenge. The importance of the problem is magnified even further for those facilities that have high energy usage, deal with hazardous materials or have sizable waste disposal issues.

November 2, 2010 By Jerry Carter and Zach Platsis

For large operations, campus facilities or companies with multiple locations an energy audit alone may not be sufficient to cover all the mitigating factors needed to be addressed. What such a company needs is a clearly written roadmap to achieving its energy and sustainability objectives.

A more comprehensive approach to energy planning

The solution for resolving the integration of energy and sustainability projects and assets in large industrial, manufacturing and institutional facilities is a fully integrated energy master plan. This is a long-term, broad-scoped plan that puts in place a company’s strategy to optimize all facets of energy efficiency and sustainability. This begins at the purchase of energy and other utilities, and covers all aspects of their use, distribution, measurement and minimization of waste. The plan establishes recommendations going forward on how to best utilize energy assets, how and when to replace them, and how to be most efficient when a company needs to add to them.

Energy master plans also provide the individualized and detailed steps to plan for energy and sustainable systems within each building of a whole-building campus or multiple-location context. The buildings, and the energy and sustainable initiatives installed within them, are totally integrated into one uniform and holistic system.

Although the components of the energy master plan are not entirely new, the necessity of putting this all together into a single integrated package is a new approach, something that many larger companies are now recognizing they need in order to make smarter energy decisions. This approach allows energy managers to recognize opportunities for conservation, sustainable design and renewable energy that more narrowly-focused energy audits might not.

An integrated energy master plan, because of its comprehensive protocol, will not only address facility operations, but process functions for review, as well. For example, integration of discrete control automation systems within different process functions in a cement plant into one centralized controls architecture can significantly reduce process cycle times, improving throughput, energy usage and equipment ROI, not to mention production per labour hour. An integrated energy master plan would address this.

A food processor that is blanching and chilling pasta in 10,000-pound batches per hour will find that by switching to a continuous cooking and chilling method it can process the same volume of pasta in the same time, while reducing its cost for heating the cooking water. An integrated energy master plan would not only discover the benefit of the continuous processing method over batch processing, but would see the energy conservation in using the spent, warmed-up chiller water as make-up water for the cooker; thereby, reducing the energy needed to bring the cooker up to its required 200° F cooking temperature.

An energy master plan which integrates facility and process functions is of critical value to an industrial, manufacturing or institutional facility. Further, such a plan takes into consideration the higher-level, long-term business goals of a company. It may be an image the corporation desires to portray, such as reflecting environmental awareness, energy conservation or possibly healthy working conditions for employees by promoting a working environment utilizing sustainable materials. In this regard, an energy master plan extends beyond those responsible for energy management, going well into the upper strata of corporate decision-making for marketing, human resources, facility operations and investor relations.

Through a systematic analysis of these interdependencies and optimized energy benefits, a much more efficient and cost-effective energy plan can be realized that takes into account the long-term business goals of a company.

The challenge of managing energy and sustainable initiatives

With the continual increases in energy costs, power quality issues and stiffer pollution regulations, the need for streamlining energy usage and providing for sustainability issues has never been stronger. Facility managers are being hit with a barrage of energy-efficiency and sustainability information from suppliers. Mandates from local, state and federal government agencies require decisions from company managers on issues which many have little previous experience handling. Additionally, the influx of incentives promoting energy-efficiency, as well as renewable and alternative energy production, demand astute attention because of the corporate benefits they can impart.

Companies may not have considered with a high level of detail what their energy asset portfolio looks like and what the optimal next incremental investment is to enhance their sustainability. Is this the year that an industrial company should be converting its fleet to natural gas? Or do the market trends show that two years from now such a switch would be half the cost or offer better tax credits, and therefore it should wait?

A manufacturer may have a budget of $3 million a year dedicated to improving its energy assets. It may have six plants in as many states with varying power consumption and power quality issues, variations in air quality, and differences in wastewater effluent and treatment processes, and a dozen other influencing factors. What is the best place for it to invest that capital?

There is continually increasing legislation from EPA regulations and local building codes on what energy and sustainable initiatives can and need to be undertaken, and what has to be reported. Many companies are unaware of these regulations, and many would not know where to begin if they were required to implement them.

It has been common practice for manufacturing, industrial and institutional facilities to contract with different suppliers to implement their energy and sustainability projects. This has the liability of a piecemeal approach where the individual projects lack full integration and foresight, which can result in non-optimized energy usage and a failure to fully realize senior management objectives.

For example, a pharmaceutical processor, to become more sustainable, may desire to install a combined heat and power (CHP) capability to offset its electric and hot water costs by capturing biogas from its wastewater treatment plant. But ten years earlier, the plant took the initiative to upgrade its wastewater treatment to an aerobic reactor, incapable of producing sufficient biogas for CHP. Had an integrated energy master plan been put in place earlier, the pharma processor would have foreseen the capability for CHP within its plant and built an anaerobic reactor instead, which produces usable biogas.

Four stages of an integrated energy master plan

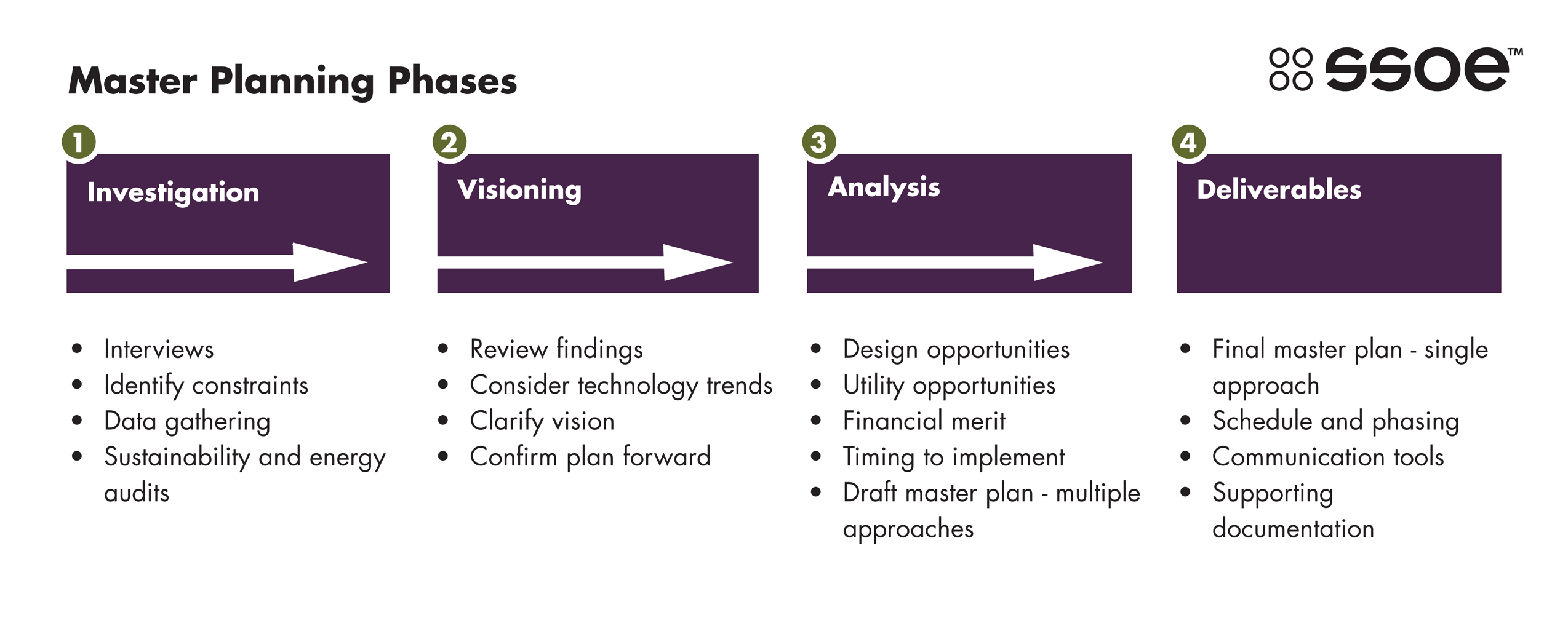

An integrated energy master plan is individualized for each company, but includes the following four-stage parameters:

1) Investigation – The first phase of an integrated and comprehensive energy master plan is investigation. What is a company trying to achieve with such an initiative? What is and what is not to be considered within the scope of the plan?

This involves interviewing key personnel relative to known and unknown problems regarding energy, production and maintenance issues. It also includes identifying constraints, such as financial, physical, cultural, zoning and any other limitations that may be intervening factors in an energy strategy.

The investigation also includes review of historical utility bills, a review of the company’s carbon footprint and emissions, gathering of relevant facility, electrical and mechanical drawings, specification sheets and automated energy management system records.

2) Visioning – This phase brings together key decision-makers, such as the CEO, the head of energy or the head of facilities, to understand what their vision is. Is it to reduce energy consumption over a period of time, to manage risks or to add renewable energy? What exactly is their goal, their vision? How do these goals tie in to the overall business objectives of the company, including factors such as product line changes and expansions, and facility build-outs or acquisitions that would influence decisions? What do they want to end up with ten years from now, so that can be backed up into a ten-year or five-year plan?

It presents an in-depth review of the findings from the Investigation phase, including quantifying and visualizing system consumption and output; benchmarking to baseline and best practice systems; summarizing objectives and critical issues; identifying opportunities to pursue; and considering potential paths to follow. This step includes a review of energy and sustainability technology trends.

Critical to this phase is a clarification and modification of the vision for the energy plan, as needed to achieve its stated goals, and to determine what is to be included and not included in the plan, as well as to determine how to manage constraints.

3) Analysis – A company now looks at all of the opportunities available, compared with the clarified vision and plan. It more closely investigates those technologies that can be utilized, and assembles basic costs and a phasing schedule to stagger the introduction of the technology as deemed most effective. A multiple-approach master plan is then drafted.

This part of the plan assesses energy and water efficiency, facility and equipment enhancements, heat and water recovery, control systems, sustainable systems, utility billing rate structure, peak shaving and shifting, and onsite power generation including renewable energy.

4) Deliverables – The final phase encompasses finalizing the energy master plan. This comprehensive plan includes an investment plan, energy targets, building sustainability targets, emissions and carbon footprint targets, operational targets, informational targets, and maintenance and upkeep targets. The plan also identifies final budget and resource commitments.

This section phases in all of the technologies and how the capital spend will be administered. It puts together any kind of internal communications tools that will be needed—such as implementing a cultural shift at the facility locations that talk about reducing water consumption or turning lights off. Everything needed to understand what this plan is, how to communicate the plan, how to present it to management, and then how to implement the plan.

Total energy management

There is clearly superior value in consolidating all of a company’s energy assets into one package. For optimized feasibility, integrating both facility and process systems with a company’s overall sustainability objectives is ideal for a complete and integrated approach.

Energy master planning is a valuable fundamental building block for all high-energy consuming industrial and manufacturing operations for reducing energy usage, utility costs and promoting sustainability, but more importantly, for providing efficient, long-term management of a company’s energy assets.

Jerry Carter is a Senior Associate, LEED AP BD+C and Business Leader and Zach Platsis is an Energy Specialist, LEED AP O+M for SSOE Group’s Sustainable and Renewable Solutions, which provides integrated services to plan and execute full-scale sustainability initiatives in single or multiple locations.

Print this page