HVAC & Plumbing

Innovative Nursing Home Saves Money with Energy Recovery Ventilation

October 7, 2011 - Founded in 1928 by Elizabeth Hart Shields Eddy, Eddy Village Green skilled nursing care centre began as a 19-bed nursing home in Troy, N.Y. Today, through an array of various housing, home care and other senior services, “The Eddy” serves more than 40,000 people in 22 counties.

October 8, 2011 By Airxchange

Administered by Northeast Health, a regional healthcare network, the system includes Eddy Village Green at Cohoes, in Cohoes, NY. Completed in 2009, this facility consists of 16 ranch-style homes modelled after The Green House, a concept that eliminates the institutional feel of traditional nursing facilities. Serving the elderly of the Albany-Schenectady-Troy area, these efficient and cost-effective units uphold and enhance Elizabeth Eddy’s original vision of safety, comfort and top-quality care.

Designed by architecture+ of Troy, each home has 12 private bedrooms and baths surrounding a core public area, which includes a small library and a family-style kitchen/living/dining area. Although they are designed with the latest technology and security in mind, they are also very comfortable thanks to efficient heating and cooling systems that operate with outside-air ventilation 24 hours a day, 365 days a year.

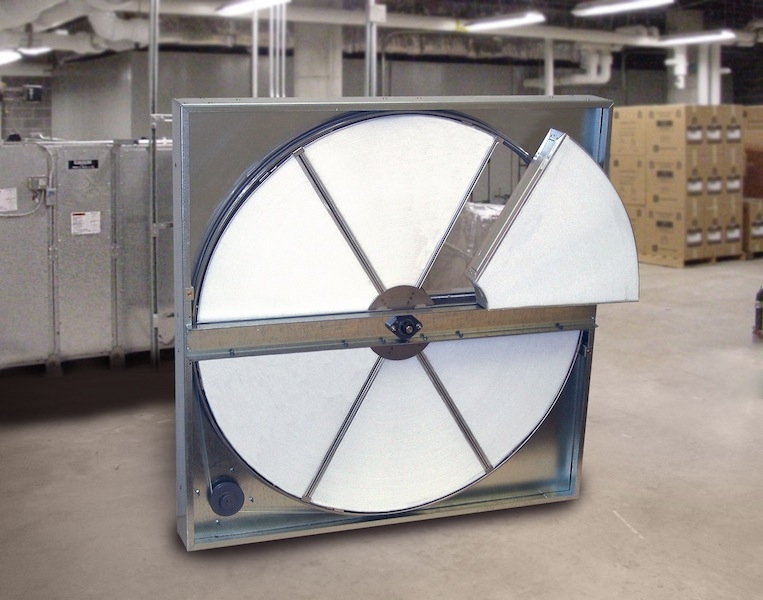

In configuring an HVAC system for the facility, the architectural/engineering firm SMRT sought a system with minimal first cost as well as minimal operating costs. In the end, SMRT designed such a system: a 13-ton unitary HVAC unit with an integrated Airxchange energy recovery wheel (also known as a heat wheel or enthalpy wheel) to supply 3500 cfm of outside air to each Green House. This energy recovery ventilation (ERV) system not only provides exceptional comfort and indoor air quality, it dramatically reduces energy costs. And, because the system operates so efficiently, SMRT was able to specify smaller HVAC units, reducing first cost as well. These units are mounted on a curb adjacent to each structure.

With units operating 24/7, SMRT wanted the most efficient system possible, and Russ Bailey, P.Eng., of SMRT knew integrated energy recovery wheels would yield significant energy savings. With rising energy costs and climate concerns, energy recovery wheels are an ideal way to reduce HVAC costs while complying with code-mandated outside air requirements. The wheels recycle the heating and cooling energy in exhaust air (not the air itself), thereby reducing the load on the HVAC system. This reduction in load not only translates into significant ongoing cost savings, but also allows the downsizing of HVAC equipment, thereby reducing first cost and providing an immediate return on investment. According to Bailey, his firm always uses energy recovery on units that are 100% outside air—units that regularly exhaust and replace all of the air in a building, not just a portion of it.

The results are impressive: based on local utility rates, Northeast Health is saving $23,168 every year compared to what the not-for-profit business would have been paying with a conventional HVAC system. The system also has proven to be reliable and easy to maintain.

“There has never been a complaint about air freshness,” says Tom Gray, Northeast Health’s director of facilities management. Gray also emphasizes the quiet operation of the system, which provides continuous comfort despite the region’s very cold winters and hot, humid summers.

“Keeping the wheel segments clean could not be easier,” adds Gray. “We slide the cassette part way out of the unit and remove the segments for quick cleaning when the filters are changed. We recently purchased a spare set for those times when an overnight soak is required to remove grease or oily contaminants.”

Submitted by Airxchange

Print this page