News

Monitoring and Verification: No Smoke and Mirrors

Here’s a big challenge for energy managers: how do you measure and verify something you can’t see? The task of convincing today’s skeptics that your actions have created energy use and cost savings can be a daunting one. Hopefully this article, prepared with the assistance of Rafael Corral, Certified Monitoring and Verification Professional (CMVP) at Energy Advantage, will shed some light on this topic.

October 8, 2009 By Peter Rowles

Verifying savings is important for an energy manager for many valid reasons. It increases job security and facilitates approval for future projects. In some cases, it is necessary to verify savings so that suppliers or ESCOs can get paid for their work. Many government agencies and utilities require monitoring and verification before releasing incentive payment. Finally, from an environmental perspective, monitoring and verification enables the creation of greenhouse gas (GHG) emission reduction credits — a valuable asset once cap and trade systems are implemented.

Providing proof can be a painful experience, as the comedian Rodney Dangerfield relates about his childhood: “I remember the time I was kidnapped and they sent a piece of my finger to my father. He said he wanted more proof.” Sometimes you just don’t get enough respect.

Energy saving projects have been popular since the oil embargo in the early 1970s and the resulting savings verification has been an issue and an impediment since the beginning. In 1994, the U.S. Department of Energy (DOE) and Lawrence Berkeley National Labs joined forces to create a standard protocol for Monitoring and Verification (M&V) which was initially published in 1996. The International Performance Monitoring and Verification Protocol (IPMVP) has been updated several times since then, with the most recent edition being released in 2007.

Basically the IPMVP provides four options to verify energy savings:

I. Retrofit Isolation: Key Parameter Measurement – Only key parameters are measured while others are assumed.

II. Retrofit Isolation: All Parameter Measurement – All of the parameters of an Energy Conservation Measure (ECM) are measured.

III. Whole Facility – Utility meters are used. Individual ECMs are not metered. This option is generally used when energy savings are substantial and the adjustments are excessively complex for Options A & B.

IV. Calibrated Simulation – A simulation model estimates the amount of energy used by a facility when there is no data available for the baseline.

It is said that the only real constant in life is change. As a result, changes occur during the implementation of an ECM that need to be considered in the savings calculation. The IPMVP divides these into Routine Adjustments and Non-Routine Adjustments.

Routine Adjustments are the factors expected to change routinely during the reporting period, such as weather, production volume, occupancy etc. Non-Routine Adjustments are those factors which are not usually expected to change, such as facility size, the design and operation of installed equipment, the number of weekly production shifts, or the type of occupants.

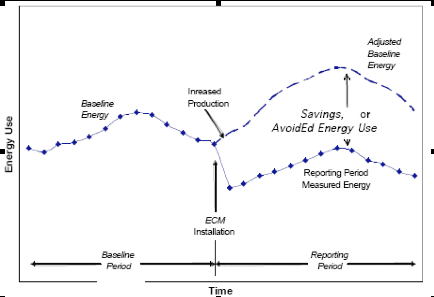

Two different models, Avoided Energy Use, or Normalized Savings are used to calculate savings based on these adjustments. In the Avoided Energy Use model, the routine and non routine adjustments are made to the baseline. The actual measured energy use is subtracted from the adjusted baseline to determine savings. This is illustrated in the following graph:

In the Normalized Savings model, the baseline energy use is adjusted to reflect “normal” operating conditions. The reporting period energy use is adjusted to reflect what would have occurred if the facility had been equipped and operated as it was in the baseline period under the same “normal” set of conditions. These normal conditions may be a long term average, or those of any other chosen period of time, other than the reporting period.

My preference is to use the Avoided Energy Use model as the adjustments are only made to one data set i.e. the baseline energy use.

The M&V Plan should be prepared and accepted by all parties before the project starts. This plan should provide a clear description of the IPMVP option being used as well as all the parameters that will be used to calculate savings.

The plan should account for the many obstacles that can affect a successful M&V project. These include:

• Impractical contract clauses

• Budget and staff constraints

• Unreliable utility data (content and supply)

• Misunderstanding of obligations and expectations

• Wrong monitoring option or duration

• Changes in building equipment and operation,

• Smoke and Mirrors

To avoid these obstacles, a qualified, independent third party should be engaged to oversee this process.

“Trust, but verify” was a favourite expression of the late President of the United States, Ronald Reagan. It is likely a favourite saying of many senior executives. Once you have verified your energy savings, what should you do next? I would recommend GHG emission reduction credits, the topic of my next article.

Peter Rowles (peter.rowles@energyadvantage.com) is the vice-president of energy efficiency / environment with Energy Advantage, a Toronto-based provider of independent energy and environmental management services.

Print this page