Commercial

HVAC & Plumbing

Industrial

Residential

Cooling systems made from metal muscles that tense and flex

February 2, 2016 - Researchers are developing a new method of cooling in which heat and cold are transferred using ‘muscles’ made from a ‘shape memory alloy’, with the aim of achieving a cooling process that does not require climatically harmful refrigerants, and should consume less energy than current technologies.

February 2, 2016 By Anthony Capkun

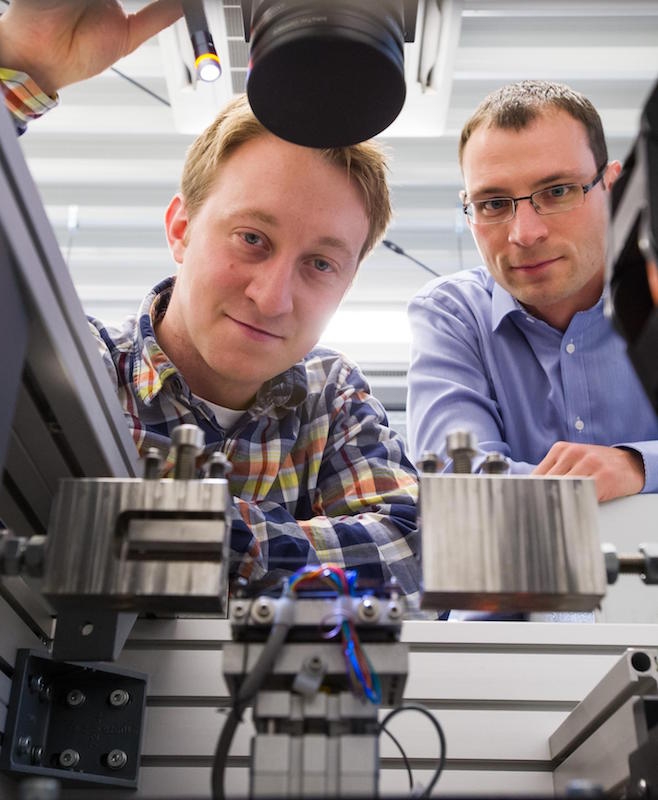

Marvin Schmidt and Johannes Ullrich from the research team headed by professors Andreas Schütze and Stefan Seelecke are working on developing an environmentally sustainable and resource-friendly cooling method. Photo Oliver Dietze.

Marvin Schmidt and Johannes Ullrich from the research team headed by professors Andreas Schütze and Stefan Seelecke are working on developing an environmentally sustainable and resource-friendly cooling method. Photo Oliver Dietze. “In our systems, shape memory alloys [SMAs] are used to remove heat,” explained Stefan Seelecke of Saarland University. “Shape memory means that wires or sheets made from a nickel-titanium alloy have a certain ability to remember their original shape […] So they are able to tense and flex like muscles. The fact that they absorb and release heat when they do so is something we exploit to achieve cooling.”

When a nickel-titanium wire or sheet is deformed or pulled in tension, the crystal lattice structure can change, creating strain within the material. This change in the crystal structure—known as a phase transition—causes the SMA to become hotter. When the stressed sample is allowed to relax after temperature equalization with the environment, it undergoes cooling to a temperature about 20 degrees below ambient.

“The basic idea was to remove heat from a space—like the interior of a refrigerator—by allowing a pre-stressed, super-elastic shape memory material to relax and, thus, cool significantly. The heat taken up in this process is then released externally to the surroundings. The SMA is then re-stressed in the surroundings, thereby raising its temperature, before the cycle begins again,” said Seelecke.

PHOTO: Marvin Schmidt and Johannes Ullrich from the research team headed by professors Andreas Schütze and Stefan Seelecke are working on developing an environmentally sustainable and resource-friendly cooling method. Photo Oliver Dietze.

Print this page