Controls & Automation

Managing Plug Load is the Next Challenge for Energy-Efficient Buildings

April 21, 2011

April 21, 2011

By Legrand/Wiremold

Take a quick look at a typical office and you see machines like computers and copiers that are essential to operating a business. Then look at individual work spaces and note the task lights, cell phone chargers, and portable electric heaters under the desk. What these and many other everyday items have in common is that they plug directly into the building’s electrical system. They constitute a building’s plug load.

April 21, 2011 By Legrand/Wiremold

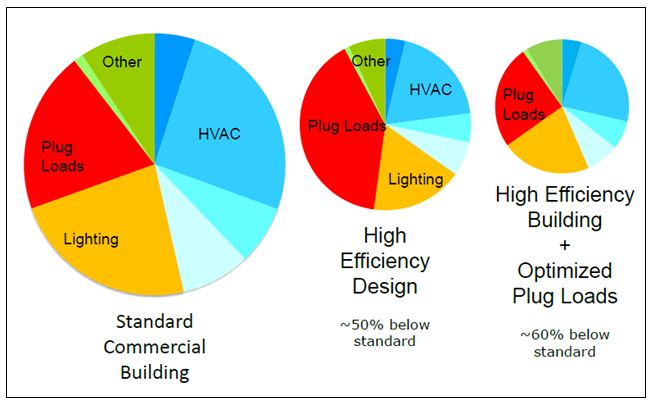

The actual plug load of a building depends on numerous factors, and no two buildings are exactly alike. Estimates of the contribution of plug load to overall building energy usage vary widely. The U.S. Department of Energy estimates that plug load represents 26% of energy use in commercial offices (Figure 1).

As the pie chart in the centre indicates, plug load as a percentage of total energy use can approach 50% when the HVAC and lighting—the largest users of energy—are reduced through efficient designs. According to David Kaneda, president of Integrated Design Associates (IDeAs) in San Jose, Calif., “Designs have become more efficient in lighting and HVAC. Now we’re looking at how buildings actually use energy and we find that plug load is a higher and higher proportion”.

As the middle pie demonstrates, improvements in lighting and HVAC efficiency have the effect of increasing plug load as a percentage of total building energy usage. Implementing a system that manages plug load can bring the energy use of a building back into proportion and save an additional 10% in energy use. This result is shown in the pie on the right.

What is plug load?

The simplest definition of plug load is: the amount of energy drawn by devices from an electrical outlet. This can be further divided into two general types of equipment: office equipment and miscellaneous equipment.

Office equipment is all the equipment that is needed to actually conduct business, such as desktop computers, monitors and copiers. Miscellaneous equipment covers items such as kitchen appliances, vending machines and water coolers in common areas and personal electronic devices that make workspaces feel more like home (i.e. desk lamps, radios, speakers, fans and small heaters). Miscellaneous equipment also includes plug-in media equipment such as televisions and projectors.

Yet another source of plug load—and one that is proliferating—is chargers for portable electronic devices.

Each of these devices draws power and contributes to plug load—sometimes even when they are switched off. Standby power is electricity used by appliances and equipment while they are switched off or not performing their primary function. That power is consumed by power supplies, circuits and sensors needed to receive a remote signal, keypads and displays including status lights. While less than the typical 5% in residential buildings, standby power use in commercial buildings is still a significant contributor to plug load.

Plug load equipment also generates heat and, as such, requires additional cooling capacity. However, the cooling demand of plug-in equipment is difficult to predict. “This area needs more study,” says Kaneda. “But there is an impact on total building energy consumption beyond the plug load itself. More plug load means more heat generated means more air-conditioning required.”

Traditionally, design teams have considered plug loads to be outside their purview because portable plug-in electrical equipment was brought into the building by the tenants. Thus, the challenge of controlling plug loads often falls to building managers, who must evaluate various strategies to employ.

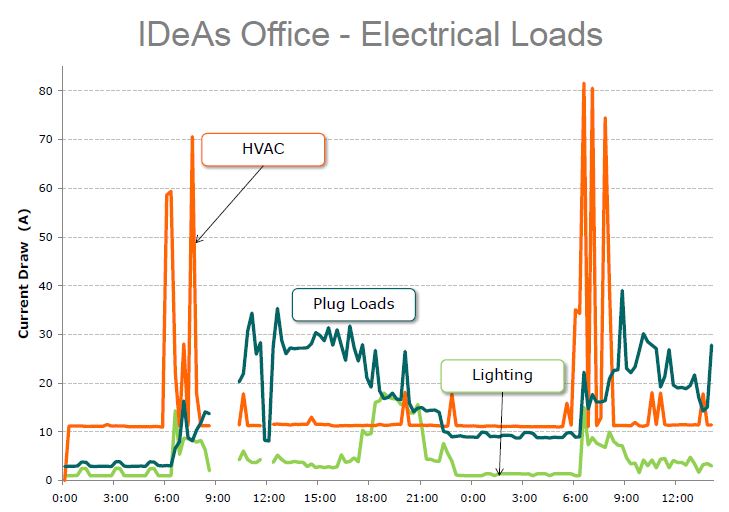

Strategies for controlling plug load As building managers become more adept at reducing the energy required for HVAC and lighting, the need to control plug load becomes greater. In the highly efficient home office of IDeAs, plug loads are nearly 50% of total energy use (Figure 2).

As building managers become more adept at reducing the energy required for HVAC and lighting, the need to control plug load becomes greater. In the highly efficient home office of IDeAs, plug loads are nearly 50% of total energy use (Figure 2).

Is the answer to reducing plug load buying and using better equipment or turning off power? According to Kaneda, the answer is probably both.

More efficient equipment

Today’s electrical devices are more efficient than those manufactured just a few years ago. However, in most commercial spaces there are many more electrical devices in use. For example, computers may be marginally more efficient (e.g. watts/calculation), but they are in much wider use than a generation ago. Flatscreens are more efficient than CRTs, but people today use larger screens and may have multiple screens at one workstation.

Turning off equipment

It is theoretically possible for individuals to turn off each piece of equipment whenever it is not in use. However, an automated approach is necessary because individuals can’t be depended on to consistently turn off equipment. Any automated system must take into account what is most appropriate to turn off. Automatically cutting power to a computer every time the user steps out of the room risks a sudden loss of data, nor would a manager want to automatically turn off the break room fridge or the aquarium in the reception area every night and weekend.

There are a number of options for controlling plug load by turning off equipment. These include:

• Automated switching using timers and “smart” power strips to power off non-critical equipment and office equipment. Beyond the timing function, these devices provide no power management capability.

• Central power management systems that use software to perform specific tasks, such as enabling sleep settings on all computers on the network.

• Total control systems that provide fully integrated management controls.

As plug loads evolve into the dominant load of a building, design teams clearly must focus on strategies to reduce this critical area of energy consumption. In fact, for the first time, a green code (IGCC, in development for the International Code Council) is going to require design teams to address plug loads. This new code will require that buildings include receptacles and electrical outlets that are controlled by occupant sensor or a time switch.

According to Kaneda, the experience of developing a Net Zero building for his own business shows that plug load is the obvious target for reduction. “Lighting has been cut so much that there is little more to be done,” he notes. “Plug loads proportionally are the worst, but that means they also offer the most potential for savings.”

This article is based on a white paper from Legrand/Wiremold. CLICK HERE to learn more about the company’s Convia Energy Management System for managing plug loads.

Print this page