Cleantech

Features

In-Depth

News

Add-on AGR technology leads to an ultra-clean natural gas furnace

March 10, 2023 By Anthony Capkun

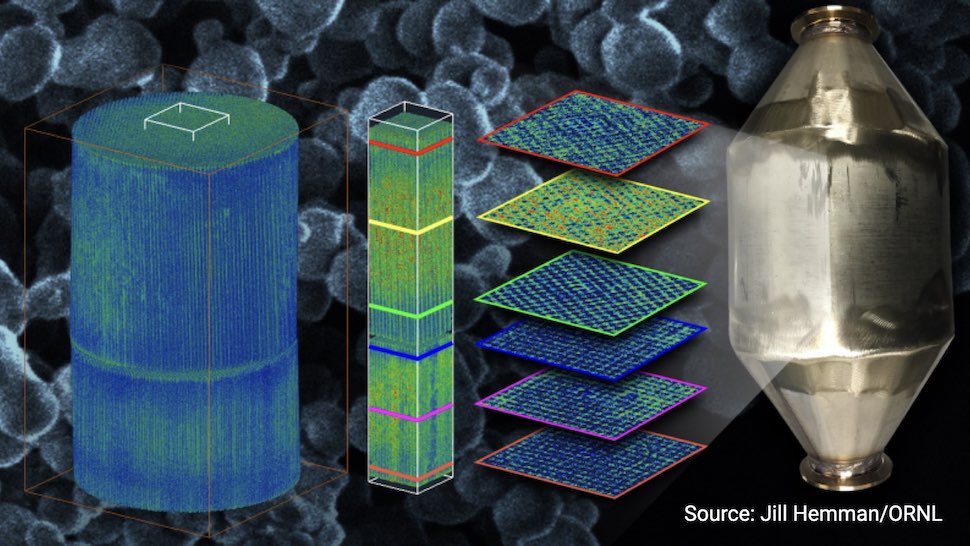

ORNL’s ultra-clean condensing high-efficiency natural gas furnace features an affordable add-on technology that can be added to other natural gas-driven equipment. Source: Jill Hemman/ORNL.

ORNL’s ultra-clean condensing high-efficiency natural gas furnace features an affordable add-on technology that can be added to other natural gas-driven equipment. Source: Jill Hemman/ORNL. March 10, 2023 – Natural gas furnaces not only heat your home, they also produce a lot of pollution.

According to Oak Ridge National Laboratory (ORNL), even modern high-efficiency condensing furnaces produce significant amounts of corrosive acidic condensation and unhealthy levels of nitrogen oxides, carbon monoxide, hydrocarbons and methane.

But maybe for not much longer.

Scientists at ORNL say they have developed an “affordable add-on technology” that removes more than 99.9% of acidic gases and other emissions to produce an ultra-clean natural gas furnace.

This acidic gas reduction (a.k.a. AGR) technology, they say, can be added to other natural gas-driven equipment, such as water heaters, commercial boilers and industrial furnaces.

“Just as catalytic converters help reduce emissions from billions of vehicles worldwide, the new AGR technology can virtually eliminate problematic greenhouse gases and acidic condensation produced by today’s new and existing residential gas furnaces,” said Zhiming Gao, staff researcher with ORNL’s Energy Science and Technology Directorate. “An eco-friendly condensate eliminates the need to use corrosion-resistant stainless steel materials for furnace heat exchangers, which reduces manufacturing costs.”

To demonstrate the effectiveness of AGR in a furnace, the researchers fabricated an AGR catalyst and enclosed it in a metal housing, then installed the device on a standard commercially available high-efficiency condensing furnace. Results after a 400-hour reliability and durability test showed the AGR almost completely removed harmful emissions from the flue gas and produced a non-acidic condensate with a neutral pH level.

AGR technology would allow furnace manufacturers to use materials that are more affordable than the stainless steels used in most heat exchangers, adds ORNL.

“Currently, AGR-enabled furnaces would require offline regeneration of the device about once every three years under normal use conditions,” Gao said. “The AGR unit could be removed by a homeowner or technician and carried to a regeneration and recycling location. This would be similar to how consumers bring their empty natural gas tanks for their outdoor grills to a dealer to exchange them for full tanks.”

Print this page