Features

Do the “Hamburger Math” and turn energy waste into profit at quick-service restaurants

Two incorrect beliefs about energy waste continually eat away at the QSR owner’s profit

July 27, 2022 By Anatoli Naoumov

Photo: Dz Lab / Adobe Stock

Photo: Dz Lab / Adobe Stock July 18, 2022 – In the competitive world of quick-service restaurants (QSR), owners are paid last. After everything and everybody else have been paid, the remaining dollars are often quite modest.

So how can a QSR franchise owner increase their take-home pay? Besides the obvious of selling more product, an often-overlooked cost is utilities: natural gas, electricity, and water.

A typical QSR (e.g. Tim Hortons, McDonald’s), spends $5000 to $7000 each month on utilities, and every dollar saved here goes directly to the owner’s bottom line.

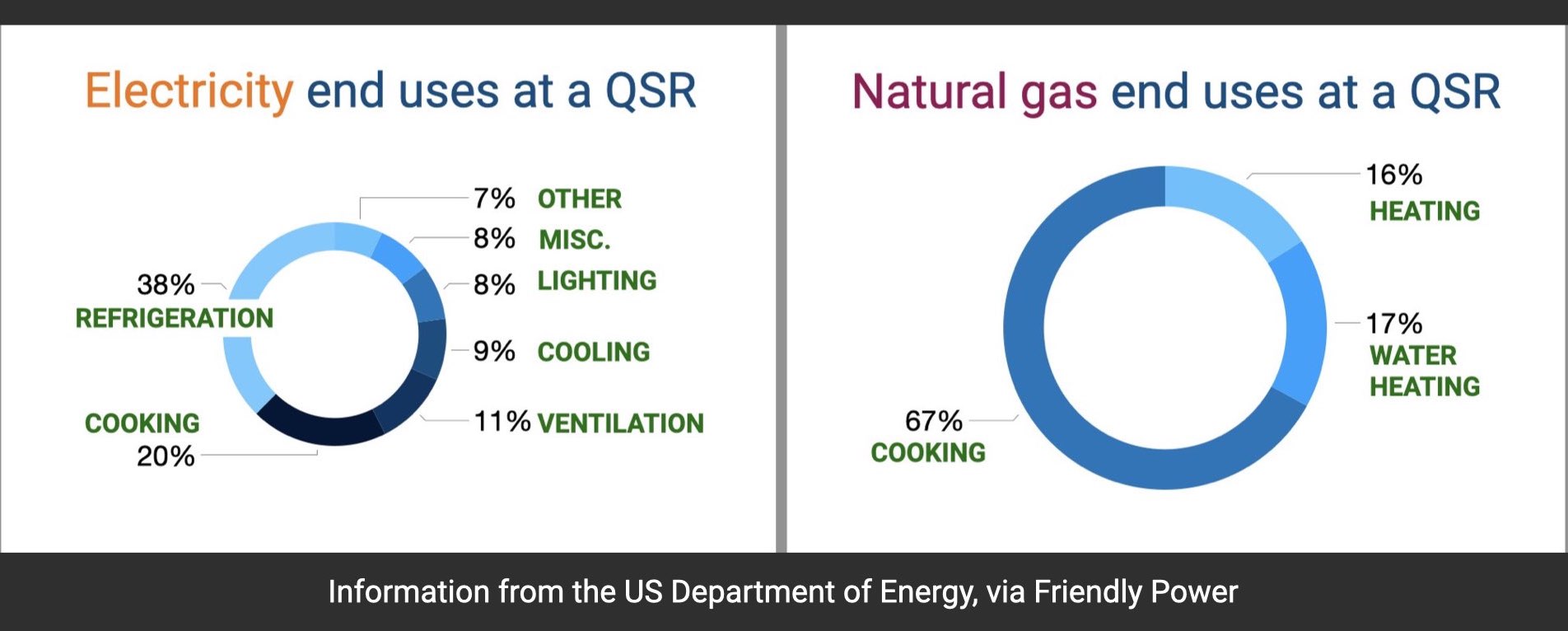

Where does energy go in a QSR?

According to information collected by the US Department of Energy and compiled into graphs by Friendly Power, about 80% of electricity and 100% of natural gas are consumed by refrigeration, cooking, HVAC, and water heating (source). These are all areas where a hard-to-notice malfunction or an operational oversight could easily cause rampant energy waste.

Open image in new tab/window to view larger version

And therein lies the problem: energy waste in refrigeration, cooking and HVAC is invisible. While it is possible to combat this waste using traditional means like audits, equipment check-ups, and preventive maintenance, the costs of undertaking such programs quickly exceed the potential savings at a quick-service restaurant.

Adopting a new belief system

Two incorrect beliefs about energy waste continually eat away at the QSR owner’s profit:

Belief #1 – Energy waste is not worth the bother

Energy waste in heating, cooling, refrigeration, and ventilation is invisible. As such, QSR owners consider energy waste immaterial, thinking it is just a cost of doing business, or “We have customers to serve, and no time or resources to tackle energy waste”.

Belief #2 – Identifying energy waste is too expensive

A standard audit will uncover whether a particular restaurant wastes energy; however, not every restaurant wastes energy, and auditing all the QSRs in a portfolio can become prohibitively expensive. Besides, even when issues are found and fixed, results cannot be guaranteed to be sustained over time (low-hanging fruit tends to grow back). Therefore, fighting energy waste at QSRs is often considered an expensive, uphill battle.

Let’s take a closer look at these misconceptions.

We start by quantifying the energy burden for a QSR owner in business terms that can be easily understood:

How many burgers do I have to sell to produce the same profit as a 10% reduction in utility costs?

Though every franchise has its own financials, I used data readily available from McDonald’s for my analysis. According to information for prospective franchisees, an owner’s take-home is $150,000 on $2.7 million in annual revenue (all dollar amounts are in US). This equates to 5.5% for the owner.

Considering that prospective franchisees are shown information from the best-case scenario, I’ll assume that a real-life owner makes 3% to 4% on gross sales. This means that a McDonald’s owner gets about 15 cents from the sale of every Big Mac priced at $3.99… the proverbial “nickel-and-dime”.

If that McDonald’s franchise burns through $6000 monthly on natural gas and electricity, a modest 10% reduction would equate to an additional $7200 going to the owner’s pocket every year.

It’s time for some Hamburger Math: how many Big Macs must the owner sell to generate the same $7200 take-home?

$7200 ÷ $0.15 = 48,000 Big Macs

However tasty, selling such pile of burgers is no small feat. If sales consisted of Big Macs only, this restaurant would sell just under 2000 burgers daily ($2.7 million ÷ $3.99 ÷ 365 = 1854).

Selling an additional 48,000 Big Macs would be like keeping the doors open for 26 extra days annually (plus additional rent, ingredients, royalty, payroll).

For a real-life QSR owner, then, a 10% energy cost reduction is the equivalent of selling an additional 48,000 Big Macs every year without being open extra days, paying additional wages, etc. It is a 7% increase in take-home pay.

Is a 10% energy cost reduction attainable? An analysis of electricity and natural gas consumption data from 900 pubs in the United Kingdom has revealed that 44% of them consumed 30% to 50% more energy compared to similar pubs operating under similar conditions (Source: kWIQly GmbH).

The excess cost is not immaterial: 1625 pounds per month (on average), or nearly half of what a typical pub owner takes home.

The analysis did not only uncover problematic pubs, it attached price tags to the waste and suggested likely causes of that waste. Most of the waste was operational in nature: settings, leaks, gaskets, dusty filters, dirty coils, etc. Fixing waste issues became a routine maintenance or management task.

Now the fun part.

The monthly investment into consumption data analysis was about the same as the cost of a pint of beer. How many pints (or burgers, muffins, etc.) should a pub or a quick service restaurant sell to put 1625 pounds into owner’s pocket?

The cost of finding energy waste

In a quick-service restaurant, energy waste can be uncovered at the cost of a burger, fries and pop combo. This is a routine maintenance task when one knows where and when to look, and what to look for.

But let’s be honest: it would be downright boring for the person who is tasked with monitoring every fridge and every thermostat. Plus, investigating all operational issues everywhere, all the time, is prohibitively time-consuming and expensive—unless you are a tireless artificial intelligence!

Such tasks are a piece of cake (pun intended) for an AI algorithm, which will identify wasteful restaurants by comparing consumption data against a big pool of restaurants.

When 500 QSRs serve the same menu using similar equipment, it stands to reason their energy consumption (after weather adjustments) must also be similar. When one of those QSRs consistently consumes more energy than the others, you know it’s time to inspect that location’s equipment and operational procedures.

AI algorithms can be pushed even further to provide a preliminary diagnostic of energy waste root causes. Some simple examples include:

• An overall higher electrical load could mean the refrigerator gasket is damaged, or the evaporator is dirty. Maybe the ventilation is running non-stop.

• Load bumps at night could mean faulty controls, or incorrect operational procedures for cleaners.

• A higher overall load in the morning compared to the evening could simply mean a higher level of operation, or maybe the morning crew is not following operational procedures.

AI is popular nowadays for good reason: it is a cheap and effective way to find energy waste in big portfolios of similar establishments. It thrives on processing huge amounts of data produced by armies of inexpensive sensors. AI-based algorithms, meantime, can produce actionable results through the analysis of data collected from existing utility meters (when data from similar locations is pooled).

So, is cutting energy cost in a quick-service restaurant well worth an owner’s attention? Is the investment in proactive energy management worth it? Do your own Hamburger Math and see for yourself.

With an international background in business analysis and development, Anatoli Naoumov, MBA, MSc, CEM, CMVP, is a managing partner of GreenQ Partners, which he founded to help business owners and facility managers unlock the value of energy management to achieve beneficial and measurable business outcomes. He is both a Certified Energy Manager and Certified Measurement & Verification Professional. A regular contributor to Energy Manager Canada, Anatoli is an active member the Association of Energy Engineers (Southern Ontario), and presented at the AEE World Energy Conference in Washington, D.C., in 2019. That same year, on behalf of GreenQ Partners, Anatoli accepted a Clean50 Top Project Award for his work on industrial refrigeration optimization. He can be reached at anaoumov@greenq.ca.

Print this page